Our Process

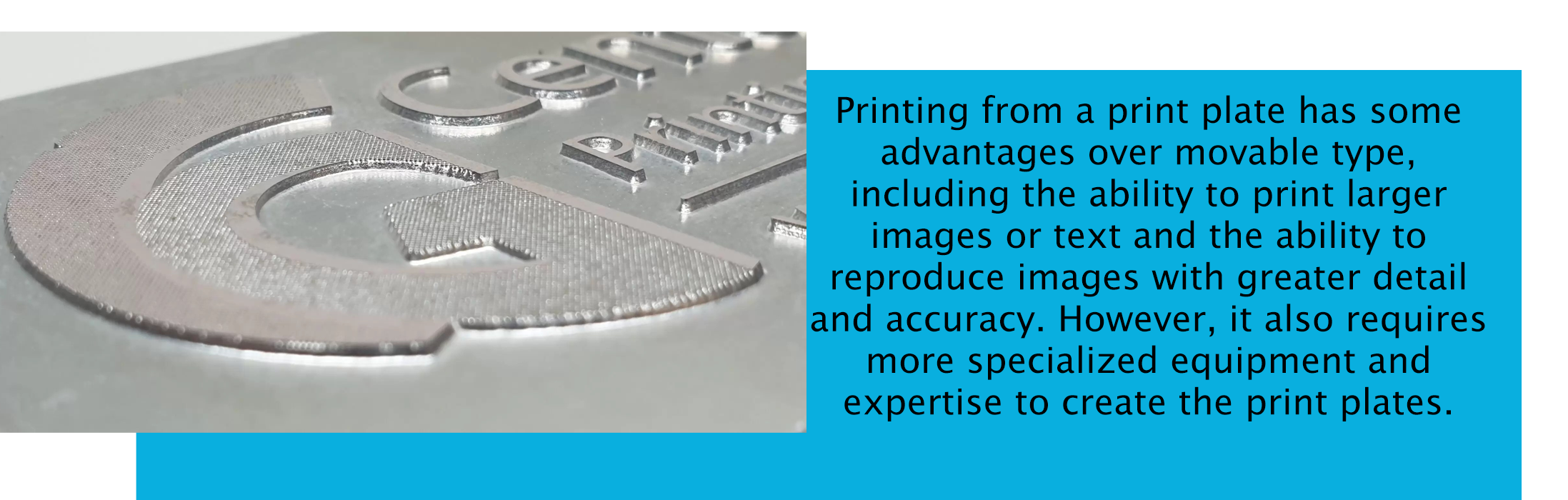

In addition to movable type, the Kugle printing presses can also be used to print from print plates. Print plates are typically made of metal or plastic and are etched or engraved with the image or text to be printed.

Here's an overview of the printing process using a print plate on a Kugle printing press:

Creating the print plate: The first step is to create the print plate. This can be done using a variety of methods, including etching, engraving, or photolithography. The print plate is then mounted on a plate cylinder on the press.

Inking the print plate: Once the print plate is mounted, ink is applied to the plate using an ink roller. The ink fills the engraved or etched areas of the plate.

Placing the paper: A sheet of paper is then placed on the press, in position to be printed. The paper is typically held in place by grippers on the press bed.

Impression: The plate cylinder then rolls over the paper with great force, pressing the inked print plate into the paper and creating an impression of the image or text.

Removing the printed sheet: After the impression is made, the paper is removed from the press. The ink is still wet at this point, so the paper is carefully handled to avoid smudging or smearing.

Drying: The printed sheet is then allowed to dry, either by hanging it up or laying it out to air dry. Depending on the ink used and the humidity, drying may take anywhere from a few hours to a few days.

Repeat: The process is then repeated for each sheet of paper to be printed.